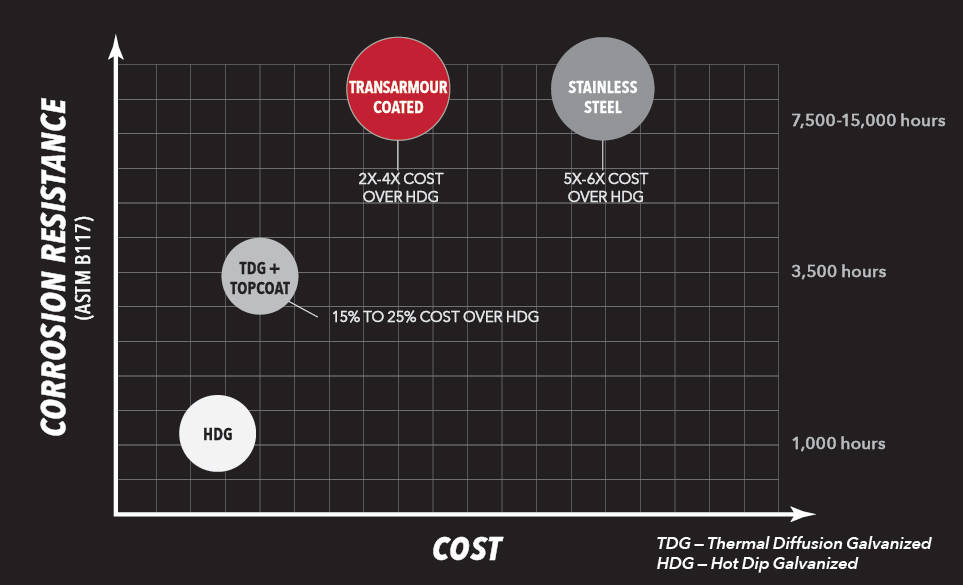

COST vs PERFORMANCE

MacLean Power offers two alternatives to stainless steel hardware. The options provide hardware with improved corrosion resistance over hot dip galvanizing, but at a significantly lower cost than stainless steel.

The protection methods available from MacLean Power balance cost with corrosion resistance to maximize the application’s benefit versus cost.

GOOD: Hot-Dip Galvanizing (HDG)

Compare the options

Greenkote® Thermal Diffusion Galvanizing (TDG)

Construction

- A coating of zinc with alloyed elements

- Process produces a harder coating which results in improved corrosion resistance over HDG

- Dark gray color

Greenkote® Thermal Diffusion Hardware

A coating of zinc with alloyed elements

Greenkote® Thermal Diffusion Hardware

A harder coating with improved corrosion resistance over Hot Dipped Galvanized hardware

Greenkote® Thermal Diffusion Hardware

Dark Gray Color

Current Applications

- Multiple large utilities are already using TDG

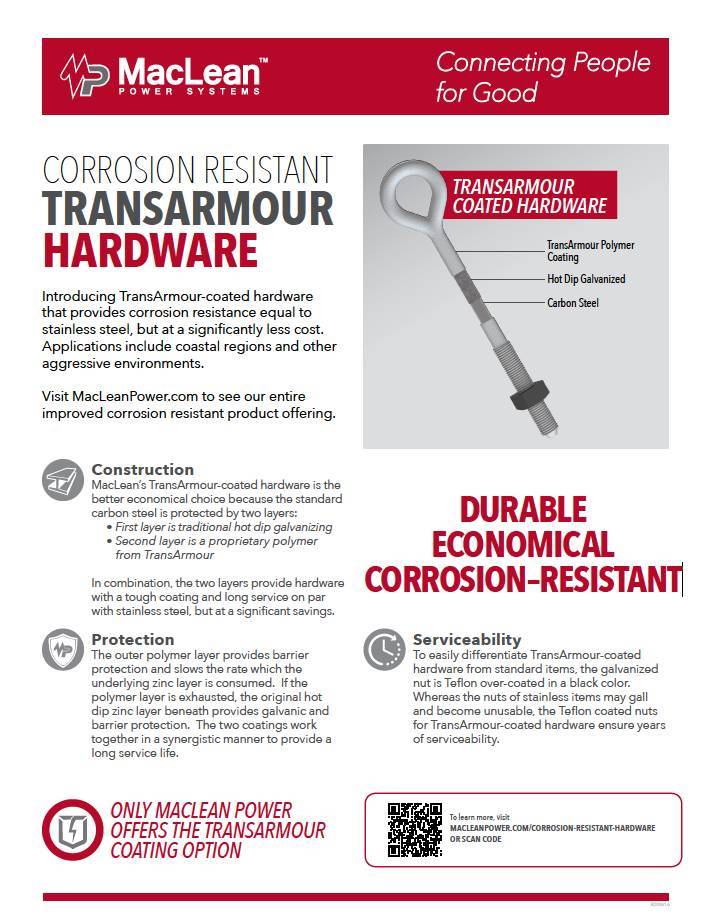

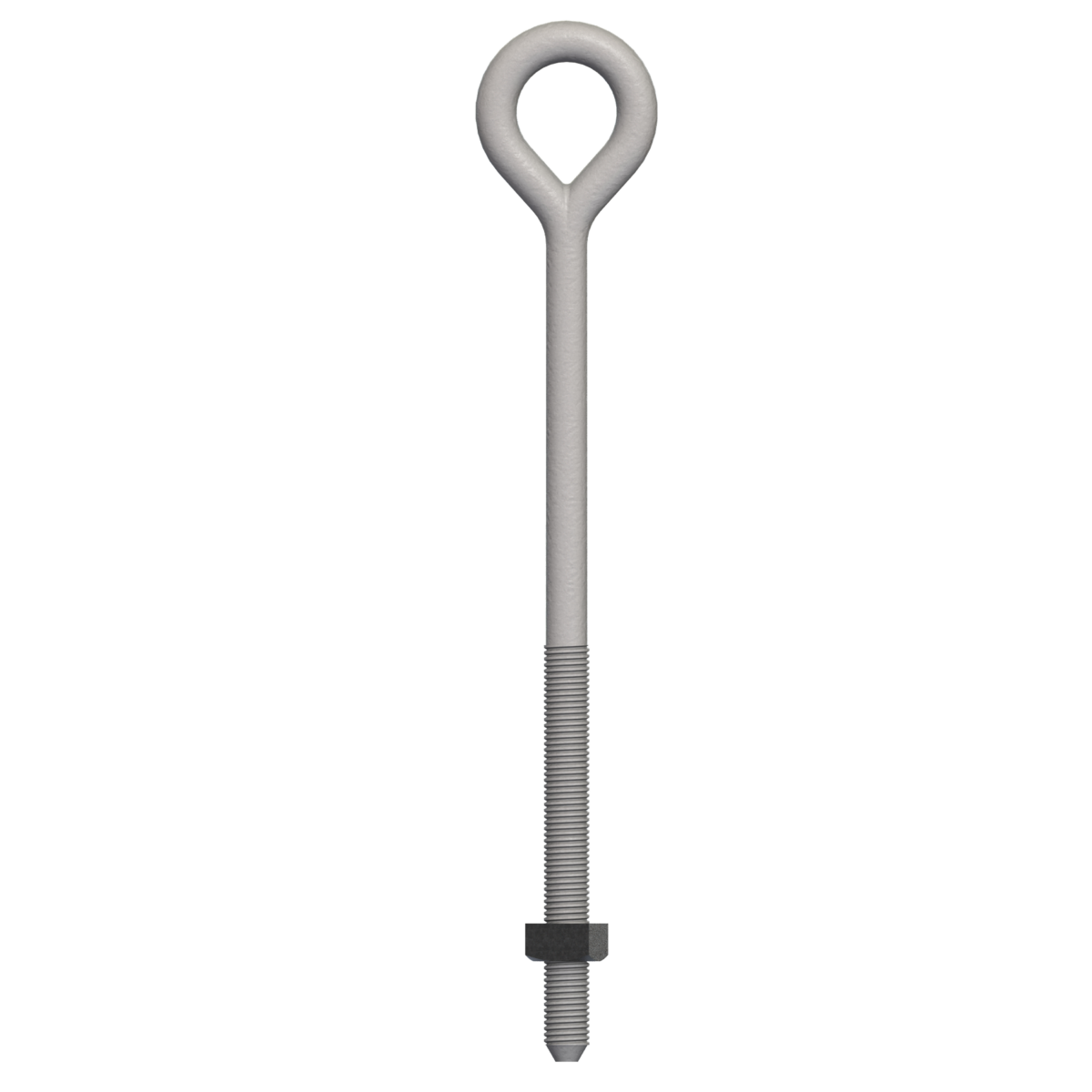

TransArmour (TA) Polymer Coating

Construction

- Hardware is coated with two protective coatings that provide a long service life

- Top coat is a proprietary polymer exclusive to MacLean Power

- Under coat is traditional hot dip galvanizing (HDG)

- Bolts are silver color

- Square nuts are hot dip galvanized and over-coated in Teflon (black color)

TransArmour Polymer Coating

Two protective coatings provide a long service life

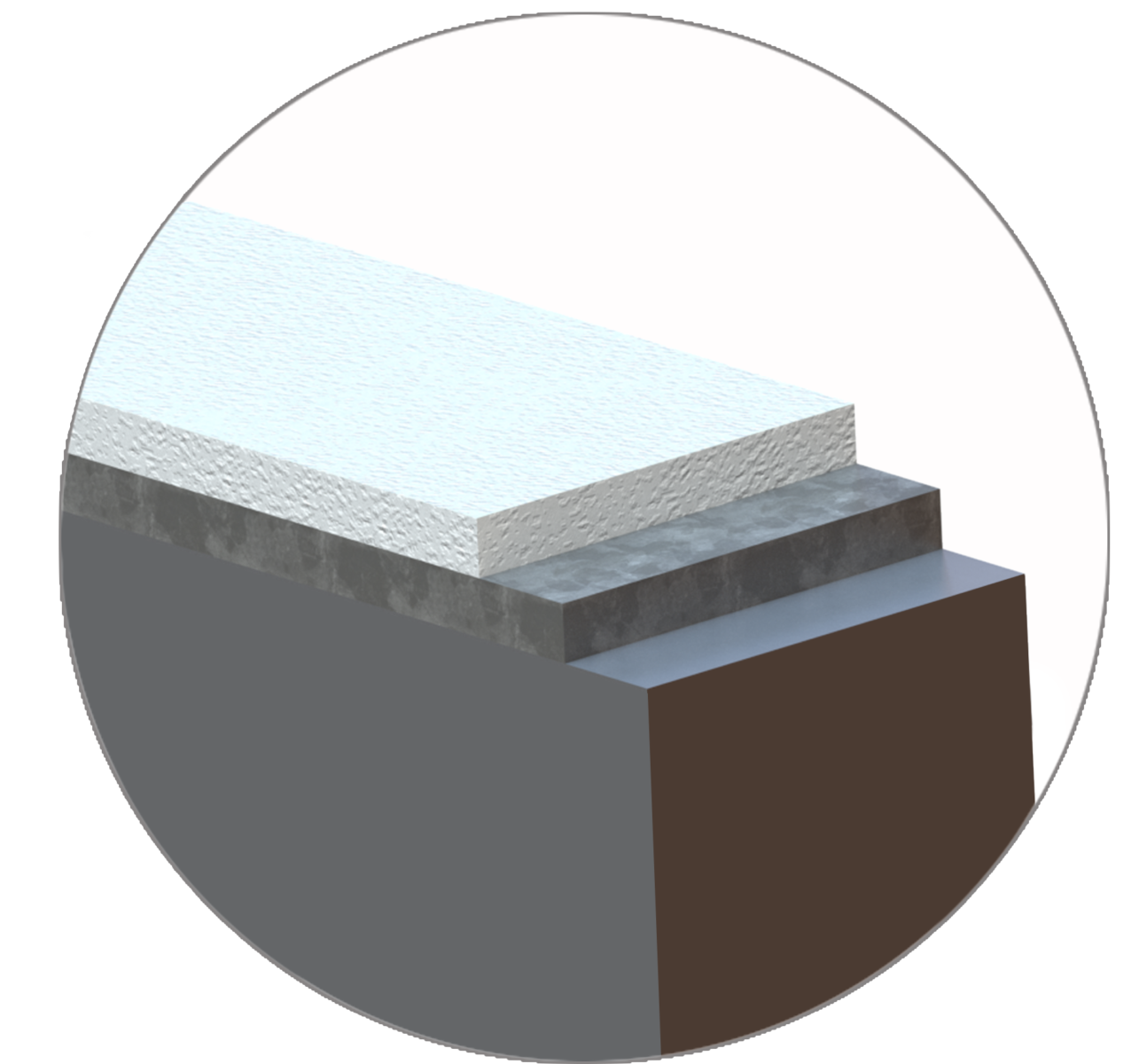

Galvanized and TransArmour Layers

MacLean’s TransArmour-coated hardware is the better economical choice because the standard carbon steel is protected by two layers:

• First layer is traditional hot dip galvanizing

• Second layer is a proprietary polymer from TransArmour

Teflon Nuts

Teflon coated nuts for TransArmour coated hardware ensure years of serviceability.

Current Applications

Similar two coating systems are used in several industries including:

-

- Transmission lattice towers

- Automotive

- Petrochemical industry

Improved Corrosion Resistant Hardware Video Comparision

TDG

TransArmour

Featured Corrosion Resistant Products

Greenkote® Thermal Diffusion Galvanizing (TDG)

TransArmour (TA) Polymer Coating

Greenkote® Thermal Diffusion Galvanizing (TDG)

TransArmour (TA) Polymer Coating

Proprietary TransArmour Polymer Coating

This layer is a proprietary polymer

from TransArmour

Hot-dip Galvanized Layer

The second layer is a traditional hot-dip galvanized layer for added protection to the hardware.

Standard Carbon Steel Construction

TransArmour hardware is constructed of standard carbon steel with protection from two additional layers.

More Information

For technical information on Greenkote® (TDG) or TransArmour hardware, please contact your local MacLean Power sales representative.

Our work keeps the the lights on

Interested in other products?