ZSP Station Class Polymer Arresters

The type "ZSP" Station Class arresters offer the benefits of polymer housings for system voltages up to 198kV.

The arresters are approximately 25% the weight of the porcelain equivalent. Handling and installation become much easier tasks.

The risk of damage to the housing is reduced compared to porcelain.

English

Metric

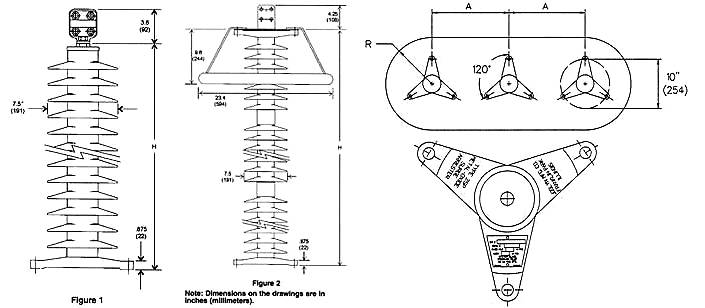

ZSP Physical Characteristics

| Catalog Number | Height (in) | Creepage (in) | A (in) | R (in) | Weight Lbs (kg) |

|---|---|---|---|---|---|

| ZSP0003- | 7.6 | 18.10 | 11 | 6 | 18 |

| ZSP0006- | 7.6 | 18.1 | 12 | 6 | 18 |

| ZSP0009- | 7.6 | 18.1 | 12 | 6 | 18 |

| ZSP0010- | 9.2 | 24.10 | 12 | 6 | 21 |

| ZSP0012- | 9.2 | 24.10 | 12 | 7 | 21 |

| ZSP0015- | 9.4 | 23.9 | 13 | 7 | 21 |

| ZSP0018- | 11 | 30. | 14 | 8 | 25 |

| ZSP0021- | 11 | 30.10 | 14 | 8 | 25 |

| ZSP0024- | 11.2 | 30.1 | 15 | 10 | 25 |

| ZSP0027- | 12.9 | 36.25 | 16 | 10 | 29 |

| ZSP0030- | 13.3 | 36.2 | 17 | 11 | 29 |

| ZSP0033- | 14 | 41.3 | 17 | 12 | 32 |

| ZSP0036- | 15.5 | 42.2 | 18 | 13 | 33 |

| ZSP0039- | 16.0 | 48.00 | 19 | 13 | 36 |

| ZSP0042- | 18.1 | 54.4 | 20 | 14 | 41 |

| ZSP0045- | 18.2 | 54.4 | 20 | 15 | 41 |

| ZSP0048- | 18.7 | 54.4 | 21 | 16 | 41 |

| ZSP0054- | 20.8 | 60.2 | 23 | 17 | 44 |

| ZSP0060- | 23.3 | 72.4 | 25 | 19 | 52 |

| ZSP0066- | 26.49 | 72.4 | 26 | 20 | 52 |

| ZSP0072-58 | 29.4 | 73.0 | 27 | 22 | 53 |

| ZSP0072- | 29.4 | 73.0 | 27 | 22 | 53 |

| ZSP0090- | 34.7 | 109.6 | 31 | 25 | 77 |

| ZSP0096- | 35.4 | 109.6 | 34 | 28 | 77 |

| ZSP0108- | 38.7 | 121.0 | 35 | 30 | 84 |

| ZSP0120- | 45.1 | 145.4 | 40 | 35 | 99 |

| ZSP0120-102 | 45.8 | 145.4 | 41 | 35 | 99 |

| ZSP0132- | 46.6 | 145.6 | 42 | 37 | 100 |

| ZSP0144- | 53 | 171.3 | 46 | 40 | 117 |

| ZSP0168- | 61.9 | 194.1 | 64 | 53 | 146 |

| ZSP0172- | 64.1 | 206.4 | 65 | 54 | 154 |

| ZSP0180- | 67.2 | 218.6 | 67 | 56 | 162 |

| ZSP0192- | 67.8 | 218.6 | 70 | 58 | 163 |

| ZSP0198- | 72.2 | 218.6 | 72 | 61 | 165 |

| ZSP0210- | 76.6 | 219.9 | 75 | 63 | 170 |

| ZSP0216- | 78 | 220.5 | 76 | 65 | 175 |

| ZSP0228- | 81.2 | 266.9 | 79 | 69 | 185 |

| ZSP0090-74 | 34.7 | 109.6 | 32 | 26 | 77 |

| ZSP0108-88 | 40.1 | 121.0 | 36 | 31 | 84 |

| ZSP0150- | 57.3 | 4624 | 63.0 | 44 | 124 |

ZSP Electrical Characteristics

| Catalog Number | UNIT RATING (kV) | MCOV RATED (kV) | TOV (1 s kV rms) | TOV (10 s kV rms) | Equivalent F.O.W. kV (Crest) | Switching Surge kV (crest) | Discharge Voltage (1.5kA) | Discharge Voltage (2.5kA) | Discharge Voltage (3kA) | Discharge Voltage (5kA) | Discharge Voltage (10kA) | Discharge Voltage (20kA) | Discharge Voltage (40kA) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ZSP0003- | 3 | 2.55 | 3.90 | 3.48 | 9.15 | 7.24 | 7.55 | 7.76 | 7.86 | 8.13 | 8.6 | 9.15 | 10.17 |

| ZSP0006- | 6 | 5.10 | 7.81 | 6.96 | 18.30 | 14.48 | 15.11 | 15.52 | 15.73 | 16.25 | 17.20 | 18.30 | 20.33 |

| ZSP0009- | 9 | 7.65 | 11.71 | 10.44 | 26.60 | 21.05 | 21.96 | 22.56 | 22.86 | 23.63 | 25.00 | 26.60 | 29.55 |

| ZSP0010- | 10 | 8.40 | 12.86 | 11.46 | 29.15 | 23.07 | 24.06 | 24.72 | 25.06 | 25.89 | 27.40 | 29.15 | 32.39 |

| ZSP0012- | 12 | 10.20 | 15.62 | 13.92 | 33.75 | 28.29 | 29.51 | 30.32 | 30.73 | 31.75 | 33.60 | 35.74 | 39.72 |

| ZSP0015- | 15 | 12.70 | 19.44 | 17.33 | 43.73 | 34.61 | 36.09 | 37.08 | 37.59 | 38.84 | 41.10 | 43.72 | 48.58 |

| ZSP0018- | 18 | 15.30 | 23.43 | 20.88 | 53.09 | 42.02 | 43.82 | 45.02 | 45.63 | 47.16 | 49.9 | 53.08 | 58.98 |

| ZSP0021- | 21 | 17.00 | 26.03 | 23.20 | 58.30 | 46.14 | 48.13 | 49.45 | 50.11 | 51.79 | 54.80 | 58.30 | 64.77 |

| ZSP0024- | 24 | 19.50 | 29.86 | 26.61 | 67.66 | 53.55 | 55.85 | 57.39 | 58.16 | 60.10 | 63.60 | 67.66 | 75.18 |

| ZSP0027- | 27 | 22.00 | 33.69 | 30.02 | 76.81 | 60.79 | 63.41 | 65.15 | 66.03 | 68.23 | 72.20 | 76.81 | 85.34 |

| ZSP0030- | 30 | 24.40 | 37.36 | 33.30 | 84.79 | 67.11 | 69.99 | 71.91 | 72.89 | 75.32 | 79.90 | 84.78 | 94.21 |

| ZSP0033- | 33 | 26.70 | 40.88 | 36.44 | 92.67 | 73.34 | 76.49 | 78.59 | 79.65 | 82.31 | 87.10 | 92.66 | 102.95 |

| ZSP0036- | 36 | 29.00 | 44.41 | 39.57 | 101.95 | 80.66 | 84.13 | 86.44 | 87.61 | 90.53 | 95.80 | 101.91 | 113.24 |

| ZSP0039- | 39 | 31.50 | 48.23 | 42.99 | 110.01 | 87.06 | 90.81 | 93.3 | 94.56 | 97.71 | 103.4 | 110.00 | 122.22 |

| ZSP0042- | 42 | 34.00 | 52.06 | 46.40 | 123.09 | 97.42 | 101.61 | 104.40 | 105.81 | 109.34 | 115.7 | 123.08 | 136.76 |

| ZSP0045- | 45 | 36.50 | 55.89 | 49.81 | 128.41 | 101.63 | 106.00 | 108.91 | 110.358 | 114.06 | 120.70 | 128.40 | 142.97 |

| ZSP0048- | 48 | 39.00 | 59.72 | 53.22 | 135.01 | 106.85 | 111.44 | 114.50 | 116.05 | 119.92 | 126.90 | 135.00 | 150.00 |

| ZSP0054- | 54 | 42.00 | 64.31 | 57.31 | 152.14 | 120.41 | 125.58 | 129.03 | 130.77 | 135.14 | 143.00 | 152.12 | 169.03 |

| ZSP0060- | 60 | 48.00 | 73.50 | 65.50 | 169.59 | 134.21 | 139.99 | 143.83 | 145.77 | 150.63 | 159.40 | 169.57 | 188.41 |

| ZSP0066- | 66 | 52.50 | 80.39 | 71.64 | 185.23 | 146.59 | 152.89 | 157.09 | 159.21 | 164.52 | 174.10 | 185.21 | 205.79 |

| ZSP0072-58 | 0072-58 | 58.00 | 88.82 | 79.15 | 203.85 | 161.33 | 168.26 | 172.88 | 175.22 | 181.06 | 191.60 | 203.82 | 226.47 |

| ZSP0072- | 72 | 57.00 | 87.29 | 77.78 | 203.85 | 161.33 | 168.26 | 172.88 | 175.22 | 181.06 | 191.60 | 203.82 | 226.47 |

| ZSP0090- | 90 | 70.00 | 107.19 | 95.52 | 246.08 | 194.75 | 203.13 | 208.70 | 211.52 | 218.58 | 231.30 | 246.06 | 273.40 |

| ZSP0096- | 96 | 76.00 | 116.38 | 103.71 | 263.42 | 208.48 | 217.44 | 223.41 | 226.43 | 233.96 | 247.60 | 263.40 | 292.66 |

| ZSP0108- | 108 | 84.00 | 128.63 | 114.63 | 288.52 | 228.35 | 238.17 | 244.70 | 248.01 | 256.28 | 271.20 | 288.50 | 320.56 |

| ZSP0120- | 120 | 98.00 | 150.07 | 133.73 | 339.07 | 268.35 | 278.88 | 287.56 | 291.45 | 301.17 | 318.70 | 339.03 | 376.70 |

| ZSP0120-102 | 0120-102 | 102.00 | 156.20 | 139.19 | 349.39 | 276.51 | 288.40 | 296.32 | 300.32 | 310.34 | 328.40 | 349.35 | 388.17 |

| ZSP0132- | 132 | 106.00 | 162.33 | 144.65 | 365.56 | 289.31 | 304.75 | 310.03 | 314.22 | 324.70 | 343.60 | 365.52 | 406.14 |

| ZSP0144- | 144 | 115.00 | 176.11 | 156.93 | 405.03 | 320.55 | 334.33 | 343.51 | 348.15 | 359.76 | 380.70 | 404.99 | 449.99 |

| ZSP0168- | 168 | 131.00 | 200.61 | 178.77 | 473.46 | 374.94 | 391.06 | 401.79 | 407.23 | 420.81 | 445.30 | 473.71 | 526.34 |

| ZSP0172- | 172 | 140.00 | 214.39 | 191.05 | 484.61 | 383.53 | 400.02 | 411.00 | 416.55 | 430.45 | 455.5 | 484.56 | 538.40 |

| ZSP0180- | 180 | 144.00 | 220.52 | 196.51 | 496.95 | 393.30 | 410.21 | 421.46 | 427.16 | 441.41 | 467.10 | 496.90 | 552.11 |

| ZSP0192- | 192 | 152.00 | 232.77 | 207.42 | 528.44 | 418.22 | 436.20 | 448.17 | 454.23 | 469.38 | 496.70 | 528.39 | 587.10 |

| ZSP0198- | 198 | 160.00 | 245.02 | 218.34 | 557.17 | 440.96 | 459.91 | 472.53 | 478.92 | 494.90 | 523.70 | 557.11 | 619.01 |

| ZSP0210- | 210 | 170.00 | 260.34 | 231.99 | 584.94 | 462.93 | 482.83 | 496.08 | 502.79 | 519.56 | 549.8 | 584.88 | 649.86 |

| ZSP0216- | 216 | 174.00 | 266.46 | 237.44 | 600.68 | 475.39 | 495.83 | 509.44 | 516.33 | 533.55 | 564.60 | 600.62 | 667.36 |

| ZSP0228- | 228 | 180.0 | 275.65 | 245.63 | 622.07 | 492.32 | 513.48 | 527.57 | 534.71 | 552.54 | 584.70 | 622.0 | 691.12 |

| ZSP0090-74 | 0090-74 | 74.00 | 113.32 | 100.98 | 256.83 | 203.26 | 212.00 | 217.82 | 220.76 | 228.12 | 241.40 | 256.80 | 285.33 |

| ZSP0108-88 | 0108-88 | 88.00 | 134.76 | 120.09 | 304.28 | 240.81 | 25117 | 258.06 | 261.55 | 270.27 | 286.00 | 304.25 | 338.05 |

| ZSP0150- | 150 | 121.00 | 185.30 | 165.12 | 432.8 | 342.53 | 357.25 | 367.06 | 372.02 | 384.43 | 406.80 | 432.75 | 480.84 |